Scope of Work

This safety plan is for the Hydrogen Fueling Station that is going to be built on Washington State University. It will describe the specific work done with the difference phases this project goes through. Moreover, hazards and risks of the Hydrogen Fuel Station will be described. It also going to quantify the amount of the hazardous materials generated, utilized, and saved. Furthermore, this plan will talk about the Organizational Safety Information, Project Safety, Communication Plan, and Other Comments or Concern, such as, acceptable Identification of Safety Vulnerabilities (ISV) Method and Safety Plan Checklist. The plan should also discuss the activities’ location (facilities’ description, personnels’ types, other operations/testing performed at the facility, and adjacent facilities) and describe the way the activities will be coordinated. This plan should list relevant permits that apply to current and planned operations.

Communication Plan and Organizational Safety Information

- Personnel Training: Personnel working at the fueling station need knowledge of hydrogen and other hazardous material (what are we planning on doing with the waste). Personnel also need knowledge of the Hazard Analysis Table and what to do in case of emergency. Employees need to know that the system…

- Safety Reviews: Safety reviews will take place as an all project member meetings where project members can express safety concerns that they have come across and the whole team can evaluate how to reduce the safety risk. During the design phase the frequency of these safety meetings will not need to be high but the frequency of the meetings will need to increase to a weekly occurrence during testing, prototyping, and manufacturing.

- Safety Events and Lessons Learned: Safety events will be reported with a short form that asks for information about what type of event happened, why it happened, who was involved, when it happened and where it happened. A meeting will be held with supervisors, anyone involved in the event and anyone whose work is related to the area or process that the event involved. At the safety event meeting, the reason the event happened will be determined and a decision will be made if there needs to be a change in the safety plan or operational procedures to prevent future events.

- Emergency Response: The system will be able to detect catastrophic safety issues like hydrogen leaks and fires, there will also be a large red button for the customer to press if they detect a fire or hydrogen leak. When one of these safety risks is present the system can automatically contact the local fire department and the project leader at WSU. No contact will need to be made with neighboring businesses because our system will be located on the edge of a wheat field. When a situation arises that puts the user in danger there will be sirens and flashing red lights to notify the customer to evacuate the area.

- Self-Audits: Audits will take the form of a walk through by a safety specialist on a weekly basis. If the safety specialist sees something unsafe happening a safety event form will be filed and the rest of the safety event procedure will be followed.

- Organizational Policies and Procedures: The safety policies and procedures are very important for the work being performed. This is necessary knowledge for the personnel in charge of the fueling station because if they were not careful, the consequences could be fatal.

- Hydrogen and Fuel Cell Experience: TBD

Project Safety

- Operating Procedures

- Operating steps

- Sample handling and transport

- Equipment and Mechanical Integrity

- Management of Change Procedures : Changes are inevitable in systems, these changes may or may not be a significant impact upon environment, safety,cost,community and integrity. Change of Management’s procedure must ensure that changes reviewed and approved by person with the required expertise to prevent workplace hazards, equipment damage, production losses. All members of the project team, project sponsors are responsible for identification, communication and management of change.

- Project Safety Documentation

We used a Failure Mode and Effect Analysis to determine the primary risks associated with the Hydrogen Refuel Project. Each system has been assessed for likely failures and prevention/mitigation measures have been provided.

The primary failure modes for this system would be:

- Loss of power

- A leak in the hydrogen system

- A leak in the Liquid Nitrogen cycle

- A fire inside the system

- A lighting strike.

- An impact by an outside force

Table of our Hazards and Safety Analysis

| System | Potential Failure Mode | Effects of Failure | Potential Causes of Failure | Prevention of potential cause of failure | Detection of potential cause of failure |

|---|---|---|---|---|---|

| Container | H2 Leak | Flammable H2 gas in container. combustion risk | Leak in system | Ventilation fans | Air Quality Sensor |

| Container | internal fire | explosion | internal combustion of H2 | Sheet Rock fire inuslation/Blast pannels to direct explosion | Fire dectection system |

| Container | Lightning strike | short to electrical system | electrical system overload | installation of lightning rod and grounding the container. | Circuit Breaker |

| Vortex Tube | H2 Leak | Flammable H2 gas in container. combustion risk | Intake pressure too high (>1400psi); Flow rate too high (>5g/s); Failure at input/output/inter connections, or Puncture. | Pressure/flow rate monitors; routine maintenance on connections | Pressure & flow rate monitors, air quality sensor. |

| Cyogenic Seperation (Purifacation) | Power Failure | TBD | Electical system failure | ||

| Cyogenic Seperation (Purifacation) | |||||

| User Interface | Power Failure | User will not be able to fill their car | Electical system failure | Backup generator | Screen will not be on |

| User Interface | Hydrogen Leak | Flammable hydrogen gas released into environment | Nozzle not seated properly, hose puncture | Shut off valve, breakaway valvue on hose | Pressure monitoring and prefilling procedure from SAE J2601 and SAE J2799 |

| Precooling | H2 Leak | Flammable H2 gas. combustion risk | Leak in system;output pressure too high (>1400psi),failure at input output connections | Pressure/flow rate monitors; | Pressure & flow rate monitors, air quality sensor |

| Precooling | LN2 leak | failure to complete the cycle to cool down H2 | Leak in system;output temperature too low (70K),failure at input output connections | ||

| Precooling | Power Failure | ||||

| Precooling | |||||

| Piping and Heat Exchangers | H2 Leak | Flammable H2 | Piping Porosity | Piping Coating | Hydrogen sensor |

| Piping and Heat Exchangers | Pipings and Fittings Failure | H2 leakage that might cause fire or explosion | Not appropriate sizes of pipes or fittings | use the appropriate material and size for piping and fittings | Fire detection + Hydrogen sensors |

| Storage | H2 gasifcation | tank will explosion | H2 gasifcation inside the tank make the pressure higher than our estimate | need a pressure sensor to make sure the pressure in control | the temperture in side the tank need keep the H2 as liquid |

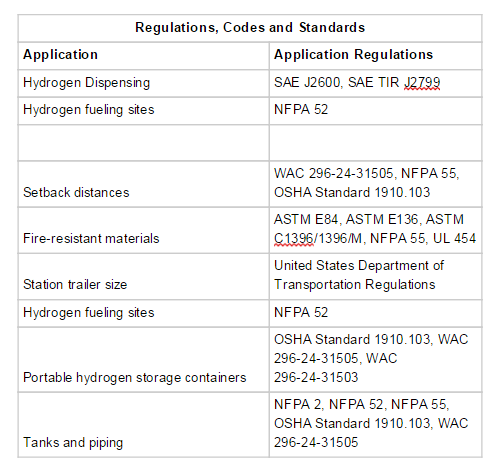

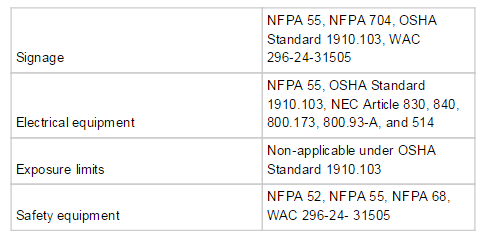

Codes to be followed: