Our method of using shipping containers to house our hydrogen fueling station lends a new level of modularity to the hydrogen fueling world that has never been seen before. This modularity will give us the unmatched ability to drag and drop our fueling stations to many location based on customer needs or desires. By evolving the concept of what a mobile hydrogen station can be, we have created a paradigm shift in the modularity and mobility of hydrogen fueling.

Background

Selected Design

Needed Modifications:

The following modification have been determined to be necessary to meet the requirements of the container.

Exterior Paint:

Flat white painted exterior to allow for the easy addition of logos and sponsorship. (Done By Dry Box)

Spark Proof Vents:

Two standard vent holes in the roof of the container to circulate air flow through the box. (Done By Dry Box)

Flat Steel Flooring:

Sheet of one eight inch steel covering the container floor installed on supports. (Done by us)

Insulation:

The insulation will consist of dry wall hung on the inside of the container over the courrigation with an insulating foam filling the gap between the two. (Done by us)

Roll Up Door:

A 4 foot roll up door will be placed on the end of the long side of the container and will house the user interface and pump (Done by Dry Box)

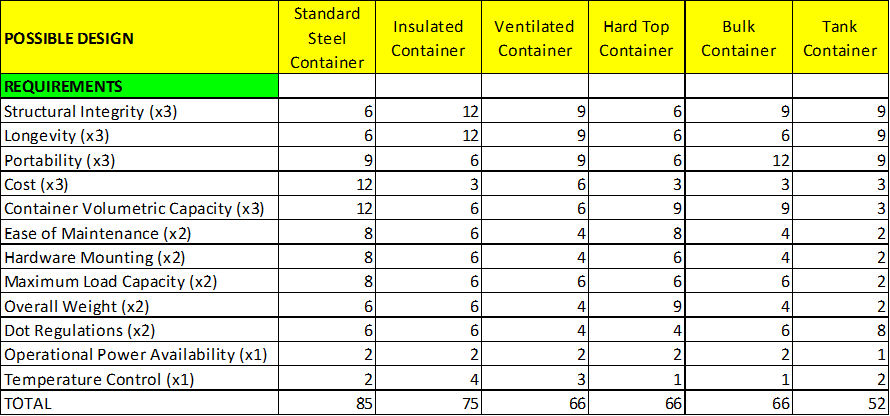

Selected Design Rationale

Current Recommendation

We are recommending the standard steel corrugated 20′ shipping container. We believe that based on the analysis of the current options this particular configuration would best fit our needs for a container that will hold all of the individual subsystems. This container option will require all shielding and fire protection to be retrofitted but we believe that it currently represents the best option to begin the building of our H2 Refuel Station.

We have chosen to order this container from Dry Box USA. This container will painted flat white and shall include the modifications of one roll up door on the side of the container to house the user interface, also two 3ftx3ft viewing windows will be installed for the purpose of educational demos of the inner workings of the system and lastly 2 spark proof vents will be installed into the roof of the container.