Innovation for Sustainable Energy

Vascular Venting

Vascular Venting Team

Goals:

- No more than 1% hydrogen by volume in the container. Hydrogen is flammable in air at 4%-75% by volume. NFPA 2 (Hydrogen technologies code)

- A network of vessels that conduct and circulate fluids.

- In the event of a hydrogen leak our system will ventilate the leaked gas.

Paradigms

Active/Passive Ventilation:

Nitrogen Flushing:

- In the event of a hydrogen leak, nitrogen will be dispensed throughout the container to eliminate the risk of Hydrogen reacting with Oxygen.

3-Stage-Integration:

- A combination of passive venting at all times, active venting when a small leak is detected, and Nitrogen flushing in the event of a critical leak seems to be the most promising solution.

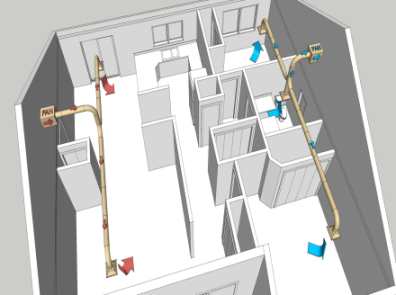

Design Recommendation: Combined Active/Passive Ventilation

What?

- Ventilator turbines

- Powered exhaust fans

- Intake vents

Why?

- Cost effective

- Simple

- Effectively meets NFPA-2 6.17 (Ventilation) standards

- 6.17.1 (Ventilation Rate) – Must be at a rate greater than 1 CFM per square foot of floor space (160 CFM for this container)

- 6.17.2.1.4.2 – Exhaust must be within 12 inches of the ceiling

- 6.17.2.1.5 (Recirculation of Exhaust) – Prevent accumulation of hydrogen within the ventilated space

- Meets AMCA 99-0401 (Spark Resistance)

Implementation

8” Ventilator Turbine:

- Passive ventilation at all times

- 255 CFM @ 4MPH winds

- Need 3 to satisfy standards

Direct Drive Aluminum Exhaust Fan:

- Active ventilation to quickly remove hydrogen

- Spark proof

- Up to 541 CFM

- Need 3 as well for ventilation standards

12” x 12” Intake Louver:

- Allow of air intake

- Capable of 310 CFM intake

- Drainable

- requires 6 air intake louvers

Economics

8” Ventilator Turbine:

Unit Price: $82.75 x 3 = $248.25

Direct Drive Aluminum Exhaust Fan:

Unit Price: $431.72 x 3 = $1,295.16

12” x 12” Intake Louver:

Unit Price: $271.00 x 6 = $1,626.00

Total Expected Cost: $3,169.41

Integration

Hydrogen Leak Detection

The hydrogen Leak Detection system will need to be able to detect Hydrogen leaks at no more than 0.6% in the container. The leak detection system is vital for the performance of the ventilation system because if you can’t detect a leak, you won’t be able to fix it. The leak detection system will be moderated sensors inside the container and will be able to activate and deactivate the active venting while the passive venting will be continuously operational.