Our Mission

With the world moving toward renewable and sustainable energy as alternative sources of power, our objective is to lead in the creation of the needed infrastructure to bypass fossil fuels. Car manufacturers are coming out with new fuel cell vehicles every year and with only a handful of fueling options available across the world, it is our goal to lead the way towards the future of hydrogen power. Across the globe, a demand has developed for liquid hydrogen to fuel the next generation of hydrogen vehicles . Leading the way toward the usage of hydrogen power, we are a team of dedicated students working to make the infrastructure of hydrogen fueling technology available, sustainable, and affordable for all.

Our Washington State University team is developing a completely new and innovative refueling system. The heart of our station is our patent pending cooling cycle. This system allows us to run at one-tenth of the pressure of currently operating systems, this increases durability and lifespan. Simple modifications would even allow for liquid hydrogen dispensing.

For our system, the WSU H2 Refuel team makes use of a recycled shipping container to house all of the components. Thus making the device movable and interchangeable. To liquefy high purity hydrogen on site, our system only needs electricity as well as an H2 source. From the Wild Horse Wind farms to an Aircraft-carrier, wherever the need may be, our system can supply.

The Basics

The downfall to any current hydrogen re-fueling station is the initial investment and the maintenance required for constant operation. Even with these problems companies are building these stations because the need is there. Our design may be the answer to both of these problems. The most expensive component in a current re-fueling station is the compressor. Due to the required purity of the output hydrogen, lubricant can not be used in the compressor. This makes the life cycle drop significantly. Just imagine a gas vehicle with no oil, it wouldn’t be long until you were stuck on the side of the road. Along with the lack of lubricant, high output pressures induce large amounts of stress on every component in the compressor.

While we have no way of getting around the lubricant free compressor, we have found a way to drop the required pressure by an order of magnitude. The normal pressure of 10,000-15,000 Psig can be dropped to 1,400 just by the use of our cooling method. Instead of compressing the gas all the way to its needed fueling value, our system liquefies the hydrogen and lets the natural boil off increase it’s pressure as it’s temperature increases.

This requirement of a lower pressure compressor decreases both our maintance cost as well as time and the total investment.

Technical Breakdown

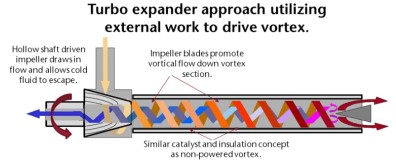

Our designs for a hydrogen liquefaction system revolve around two main components: our patent pending vortex tube technology and our patent pending cryogenic thermal compression dispensing; reducing the number of moving parts necessary for operation. The process starts with ultra high purity hydrogen (>99.995% hydrogen), this hydrogen will be compressed to 1400 psig. This hydrogen flows through a liquid nitrogen bath for pre-cooling to 77 K before entering the vortex tube.

The vortex tube is a motionless device which separates fluid flow into low and high energy components. The Cold end supplies hydrogen (approx 40 K) to a J-T Valve for expansion. This expansion will significantly drop the temperature and a fraction of the gas will liquefy. While the hot end of the vortex tube is recirculated back to our compressor so that no hydrogen is wasted.

Once stored, the liquid hydrogen is allowed to boil, achieving the necessary pressure of 700 bar (10000 psi) for dispensing. This design eliminates the need to compress fuel to the dispensing pressure, as it occurs naturally during hydrogen boil off. The process includes the following steps:

In order for hydrogen to be a viable fuel alternative, a re-fueling infrastructure will need to be implemented. The refueling system that Washington State University is working on can help fill that void in an economical and environmentally friendly way.

WSU H2 Refuel is utilizing patent protected vortex tube technology to produce super cooled hydrogen at record setting efficiencies. The following lists a few ways in which our system is superior over those already in progress:

- Hydrogen catalyzing vortex tube

- First usage of a catalyst lined vortex tube use in hydrogen liquefaction

- Catalyst converts between two hydrogen energy states to improve overall liquefaction efficiency

- Movable dispensing unit

- Entire liquefaction process will be housed inside a shipping container for easy movement if necessary

- Modular unit for easy upgrades and repairs

- Reduced compressor requirements

- Most station compressors must operate at 10,000 psi, ours only needs 200 psi

- Smaller, simpler system reduces maintenance

Ideally our design would include:

- Biomass source

- Hydrogen produced on site by bacterial metabolism in bioreactors

- Potential waste management process using wastewater or agricultural byproducts to produce hydrogen

- This would be a low energy input/high energy output part of a future process

- On site production

- Dispensing unit attached to production system

- Purifying system

Building a Reputation

We were one of six teams to compete in the 2016 H2-Refuel competition to create a hydrogen refueling station. The key competition requirements were as follows:

- Station must operate at 700 bar or higher

- Must dispense (fill up a tank) 50 times a day in 3 minutes or less per refuel

- Operate effectively 98% of the time

- Cost $5/kg or less to produce

- Cost the user no more than $8 per kg

Interested in Supporting the Next Generation of Refueling?

Click here to be directed to the “How You Can Help” page.