Background

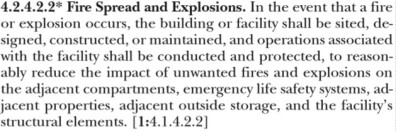

Provide fire resistance for the system through insulation that complies with NFPA 2 standards. Maintain a safe fire resistant system while meeting the code for fire resistance with respect to hydrogen. As well as fire resistance, we need to compensate for cryogenic temperatures. Part of liquefying hydrogen means getting it down to 20° Kelvin. At 20° Kelvin water readily condenses out of the atmosphere and would form ice on most of our components. Another goal of the Insulation team is to ensure that codes are satisfied with respect to ice forming on the outsides of the tubes and equipment inn our system.

Paradigms

Suppress Sound Engineered Drywall

Next generation sheetrock with high-performance sound and vibration absorbing with fire resistant properties. While meeting basic ASTM E codes for fire and sound proofing it is quite expensive being $70 rather than $11 like the USG Gypsum board. This dry wall is fire resistant (1 hr fire rating), sound resistant and non metallic. There was no specification if it could or could not be attached to metal. It however degrades with exposure to any moisture. Does not interfere with cell phone reception, wireless networks or operation and equipment links. Available with non-toxic, biodegradable, and anti-mold properties. It is fire-rated ASTM E 84 and ASTM E 119.

USG Sheetrock Gypsum Panels

Gypsum board is an insulation made up of a gypsum core and multi-layered laminated face paper to control water absorption, provide maximum plaster bond and resist sag. Given that this drywall is very durable in many scenarios, it can be used with wooden or metal framing. In our case, this sheetrock would be mounted straight onto metal Bosch tubing allowing use to make a standard size for all containers overall. The USG Gypsum board also has a rigid bad for economical application. Additionally, this product meets the fire codes necessary for this project, so fire started inside the container will not be spread forth. While meeting all required codes necessary it USG also has the added bonus of meeting the Code X requirement allowing it to be even more compatible for hydrogen storage, with an added resistance to heat and fire. A drawback to this insulation, is that it is not suitable for environments with moisture and it is not sound proof, but it does help minimize sound exiting the container.

Decision

Using ⅝ inch USG gypsum boards, meets more standards with the added code X, costs significantly less, is geared more towards fire/thermal safety rather than sound reduction which isn’t the primary focus. Can also buy from Pullman Building Supply making it very convenient while still remaining cheap at just over $11 a sheet compared to the $70 a sheet.

Implementation

- Will need drywall screws that will work for bosch tubing.

- Using 4’x8′ panels with a thickness of ⅝ inch.

- Needs to cover the walls completely excluding the rolling door but including the top and side doors

- Will need to use C channels and metal studs to create a sub-frame for the insulation

Integration

Issues we had to solve:

- Potential issues were: drywall damage, difficulty getting the drywall in with the bosch tubing and attaching the bosch tubing to the walls of the container, knowing where holes will need to be cut for ventilation, affixing drywall on the doors and around the window and rolling door. Also will need to find out how wiring is going to be implemented so we can figure out any holes we will have to make in the drywall.

- Communication with ventilation group, power group, and system integration group.

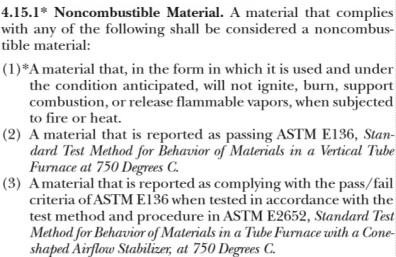

Codes Needed to Comply:

Future

The Insulation of this refueling station is not really a part of the system that will see dramatic improvement within the coming years. with that in mind it is likely that we will not change our decisions and implementations for future projects.