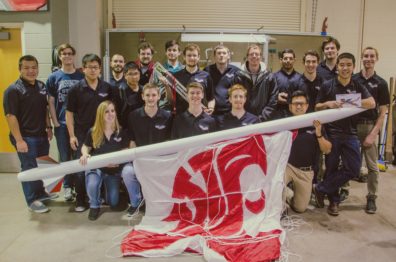

Great Team, Great Year

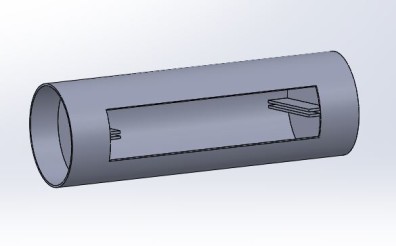

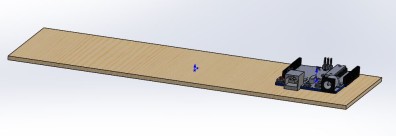

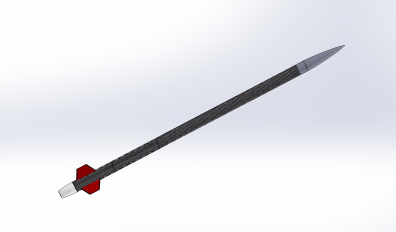

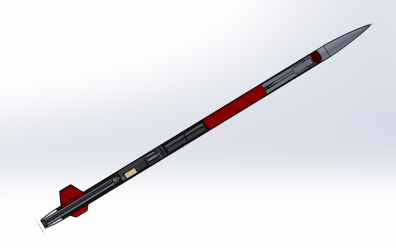

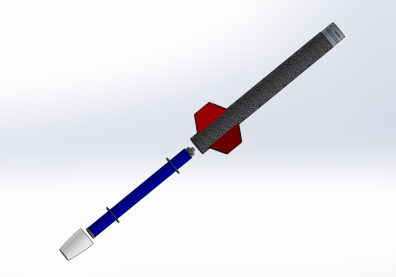

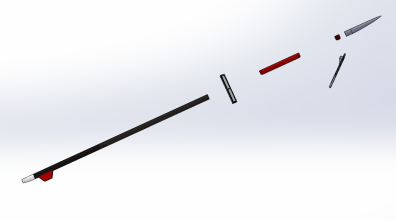

paul.flerchingerIt has been a great year for the WSU Aerospace Club. We have excelled in innovations, attempted new challenges, and grown even larger. This is the second year the club will be attending IREC and the WSU Aerospace Club has shown true dedication and excitement for the event. We have researched, manufactured, and tested our own propellant, which is no small task. We have created a parachute system that not only is designed and hand made, but also autonomously guided by GPS coordinates. We have created a 34″ wingspan glider that fits into a 4.5″ body tube and will autonomously glide back to the launch site with GPS coordinates. We have created a new electronic system with an upgraded arming mechanism and we have built an all carbon fiber fuselage with a stunning paint scheme.

All of this is possible due to the hard work that each of the club members put in for the past 8 months. It takes exceptional students to come in every Friday and work hard after a full week of school. This year is truly one for the books and I hope all of the members are proud of their accomplishments.

Ladies and Gentlemen, this is what makes clubs so exciting and impressive. Never stop improving and encouraging each other to conquer new challenges. You can do it!